Two stroke motorbikes dominated the sport for decades

Two stroke engines are a type of internal combustion engine, it was invented by Scottish engineer Dugald Clerk in 1881. The principle of a two stroke engine is that the process of intake, compression, power and exhaust is completed in two strokes of the piston, compared to an engine with four strokes. The result is a very high power to displacement ratio, potentially even double the power from a similar sized four stroke.. Two stoke engines come in all sizes and also come in diesel variations. When two strokes were introduced they quickly became popular on motorbikes for their power to weight ratio, alternatively diesel two strokes became popular in Trains, large boats, and power generation applications.

Ridiculous double two stroke engine drag bike.

As mentioned above a two stroke works completes the internal combustion process in two strokes. Also different to a four stroke engine is the intake and exhaust system. A two stroke engine utilises ports or openings in the cylinder to deliver fuel and remove exhaust.

The two stroke cycle

The piston in a two stroke engine also acts as a valve, the up and down movement of the piston uncovers the intake, exhaust and transfer ports at precise moments. Some two stroke engines has different systems but most operate on the principle. Fuel and air mixture coming from the carburettor enters the cylinder through the intake port below the piston, this mixture enters the crankcase and is pressurised by the cylinder which is now on a power stroke. The downward motion of the piston now uncovers the transfer port, this port transfers fuel-air mix from below the piston to above the piston. This intake also helps expel the the exhaust from the last power stroke. The piston now on its upward stroke covers all of the ports and compresses the fuel air mixture, when the piston reaches T.D.C the spark plug ignites the fuel and the process begins again.

Diesel two stroke for a Large ship

What is happening below and above the piston?

Above the piston is the inlet of fuel through the transfer port, the compression of that fuel, and the ignition of that fuel resulting in a power stroke. Below the piston is the inlet port where fuel-air mix enters through a reed valve, then the mixture is pre compressed by the downward motion of the piston, the mixture then travel through the transfer port when the port is uncovered.

Why must roller and ball race bearings be used on 2 stroke SI engine crankshafts?

Because a two stroke engine is a sealed unit there is no way for oil to be circulated to lubricate the parts. Lubrication in a two stroke is done by the fuel entering the system. two stroke fuel contains a preset amount of oil which lubricates the parts and bearings of and engine before it is ignited, this oil also cause some of the emission problems that two strokes have. The reason for ball race bearing is so this oil can penetrate between the ball bearing and lubricate them, if this was a closed bearing the oil would not perform it's job and the engine could seize.

Two stroke ball race bearing

Why are rollers caged in crankshaft bearings?

Crankshaft roller bearings are caged to prevent the individual rollers from moving around the big bearing. The constant movement of the bearing from the piston would make the rollers bunch together on the bearing leaving some surfaces with no roller protection.

Roller bearings of different sizes

A one piece crank shaft cannot be disassembled, the bearings on the centre of the crankshaft need to be replaced after an amount of time as they suffer engine wear. This is the reason for the split bearing, it can be split and removed from the crankshaft and replaced with a new bearing.

Split type caged roller bearing

Why do we have pins between the piston ring gaps on a 2 stroke?

A pin on the piston stops the piston ring from moving around the piston. the repeated motion of the piston can move the piston rings and in a two stroke if the piston ring gap is in the wrong place then this could cause pressure loss.

A piston with piston rings, gudgeon pin and piston ring pins.

How does a reed valve work on a two stroke?

A reed valve is a type of one way valve. It is essentially just a flap that opens one way. They are used on a two stroke engine to allow the entry of fuel i the crankcase. The movement of the piston creates a vacuum this vacuum 'pulls' air and fuel through the reed valve when the vacuum stops the valve closes.

A two stroke reed valve

How do you check a reed valve?

The constant opening of this flap can damage the reed valve where it becomes inefficient and does not close properly. Dirt can also make the valve not work properly. The reed valve can be checked by holding it up to light and inspecting it, if there is a gap the reed valve needs repairing or replacing.

Explain the term ovality and taper and how are they formed?

Taper and Ovality are terms for wear in the cylinder bore of an engine. Due to the constant stress that an engine operates with the cylinders and bore are subjected to wear. Taper is the wear which makes the cylinder bore taper or wear outwards, It is caused by the constant sideways movement of the piston translating linear motion into rotational motion. Ovality is the wear on a cylinder bore which turns the circular bore into a more oval shape, this is again because of the repeated movement of the piston.

an example of cylinder bore wear

How does the piston rings seal in the bore?

The piston rings purpose is to ensure there is a seal in the cylinder around the piston, and to transfer heat from the piston through convection to the cylinder block. Without a proper seal much power would be lost and proper compression would not be achieved. They achieve this seal due to the ring pushing the bore and also due to the rings design. When combustion happens in a cylinder some of the force of combustion goes in the piston ring gap and behind the piston ring and force the ring into the cylinder bore creating a strong seal. the piston ring also prevents excess oil from being burnt in combustion.

Another example of cylinder wear

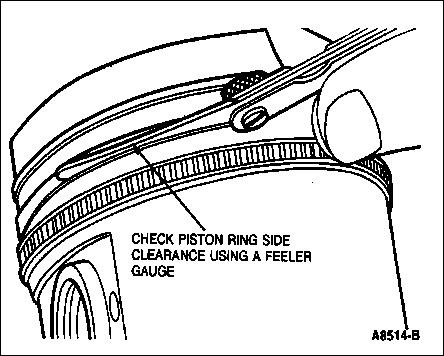

What is meant by the terms groove depth, side clearance and end gap on the pistons rings?

Groove depth:

This is the depth of the groove that the piston ring sits in. This groove is prone to carbon build up and effect the piston rig operation.

Side clearance:

This is the amount of space that is between the piston ring and the piston groove wall, this is measured with a feeler gauge.

End gap:

This is the size of the gap that is on the piston ring, this gap can change due to the changing ductility of the ring. This is measured with a feeler gauge while the ring is in the cylinder to determine it's natural position.

While they are both internal combustion engines there are several differences between a four stroke engine and a two stroke engine, the main differences are in the fuel delivery systems. A two stroke engine completes the engine process of intake,compression, power and exhaust in two strokes of the piston that is one movement down and one movement up. As mentioned above a two stroke utilises the movement of the piston and intake and exhaust ports on the cylinder bore to deliver the fuel to the system, as opposed to the valve system on a four stroke. The fuel in a two stroke engine, unlike 4 stroke, also contains oil as the engine is a sealed unit and needs lubrication. Two stroke engines are predominantly air cooled because of their simplicity, apart from marine two strokes.

Mechanical Efficiency:

Mechanical efficiency is a term used to describe how efficient a machine is (in this case an engine) 100% efficiency would mean that all of the energy produced by the engine would be used, this is quite impossible though as engines lose energy through friction heat and noise.

A maglev train has very high mechanical efficiency as the train does not come into contact with the rails and is sitting on a 'cousion' of magnetic field. The electromagnets on the train are propelled by the opposite

magnetic force from the magnets on the track.

Thermal Efficiency:

Thermal efficiency is a measure of the amount of heat produced by a machine, and how much of that heat is wasted. This figure is put into a percentage of thermal efficiency.

Volumetric Efficiency:

Volumetric efficiency is a measure of the movement of a fluid ( air, fuel) into a space. In internal combustion engines this is how easy it is for a charge to enter or exit the cylinder. This efficiency can be increased by removing bends in intake and exhaust pipes. A turbo charger decreases volumetric efficiency by slowing down the exhaust gas leaving the engine to drive the turbine, however makes up for this energy sap with the power it produces.

List 2 methods of lubricating the internal parts of 2 stroke S.I. engines?

As mentioned before may two stroke engines have oil in the fuel which lubricates the engine parts. Another method of lubrication is having a wet sump, this system utilises oil that is poured into the crankcase and is a high enough level that the crankshaft and big end bearing are submerged at BDC, the movement of the piston splashes oil up on to the walls of the cylinder and the piston. In four stroke engines the oil is pumped to the top of the cylinder.

This is a four stoke system.

What happens if the piston gap is too big?

If the Piston ring gap is too big then the cylinder could lose compression due to the large gap on a piston ring.

What happens if the piston gap is too small?

If the gap is too small then the piston ring will not be able to expand as much. If the piston ring cannot expand then it may not seal the bore properly, leading to poor compression.

Although Two stroke engines have lost some popularity due to emission constraints they are still a popular choice for small engines like chainsaws as they are very simple and easy to produce and they can operate sideways or upside down due to the ports. Nearly all of the biggest ships in the world use low speed two stroke diesel engines, so in a way two stroke engines have revolutionised the world by allowing goods to be

transported vast distances efficiently.

You got to have balls to ride death machine like a two stroke racing bike

References:

http://en.wikipedia.org/wiki/Two-stroke_engine

http://science.howstuffworks.com/transport/engines-equipment/two-stroke.htm

http://auto.howstuffworks.com/diesel-two-stroke.htm

http://en.wikipedia.org/wiki/Volumetric_efficiency

http://en.wikipedia.org/wiki/Thermal_efficiency

http://en.wikipedia.org/wiki/Mechanical_efficiency

http://en.wikipedia.org/wiki/Piston_ring

Awesome work well done

ReplyDelete