Explain the terms:

Conduction:

Conduction is the transfer of heat between objects of matter (solids). Heat moves from an area of high temperature to areas of lower temperature this is the basis of heat transfer in engines.

Conduction in a simple experiment.

Convection:

Convection is the transfer of heat in fluids (Air,Liquid), heat is transferred by molecules and follow a current of heat transfer called a convection current. heat can be removed from one area and be localised in another area, like in a heat transfer unit in a engine.

Simple diagram of a convection current

Radiation:

Radiation is the transfer of heat through empty space, heat emitted from an object or liquid travels out into cooler empty space or air. This principle is the basis of the radiator in a car.

What is Direct cooling

Direct cooling in a marine application, is the cooling of an engine with a raw water pump system. This system works by drawing raw water (either salt water or fresh water) in through a port on the bottom of the boat called the sea cock. This raw water is then drawn through filters by a powerful pump and circulated through the water jackets of the engine, the heat from the engine is transferred to water. this water is then expelled from the engine. This type of cooling is very effective, however drawing raw water (especially salt water) through an engine can severely corrode the engines water jackets and damage the engine unless corrosion protection measures are in place. Another type of Direct engine cooling in automotive use is air cooling. This is where an engine is cooled by air flow over the hot cylinder block. Large fins are moulded on to the block to increase the surface area and therefore increase the radiation heat transfer quality's.

Simple Raw water intake system diagram

Just because i can, the most powerful air cooled radial engine. The pratt and whitney R-4360 major, Four radial engines connected to a common crank shaft with 28 pistons!

What is indirect cooling?

Indirect cooling in a marine application is a cooling system that draws heat away from the engine with water and cools the water using a heat exchanger. In some respects it is similar to a car radiator system. Water that is circulating around the engine block draws heat away from the engine parts. This hot water is pumped to the heat exchanger, this device works by drawing raw water through a similar system to direct marine cooling but the raw water is only pumped through the heat exchanger the hot water circulating the engine transfers it's heat to the colder raw water which is then expelled from the system. This solves the problem of direct cooling corroding an engine block with raw water, this system leaves only the interior of the heat exchanger corroded which car be quite easily replaced. The now cooled fresh circulating water is sent back to the cylinder block water jackets. Most modern marine engine use this cooling system. In the automotive trade a water pump circulates water around the engine and the water is cooled in a radiator which is exposed to air flow.

What is the purpose of a thermostat?

A thermostat is a device in engines that is designed to keep temperature at a preset constant. Engines have a optimum operating temperature which the thermostat trys to control. It works like a switch and opens to release a flow of cold water through the cooling system when a preset temperature on the thermostat is reached the thermostat will open. A thermostat that does not operate correctly can make an engine overheat.

The core of a heat exchanger has to deal with high temperatures and the corosiveness of fresh and salt water. So therefore it is made of a strong metal with a high corrosion resistance. Heat exchangers come in different types like Plate type and shell and tube type heat exchanger. A plate type is now the most common and efficient type, it utilises plates with flowing hot water being cooled by cold raw water flowing through an adjacent plate.

How does the centrifugal circulating water pump work?

In a liquid cooled engine, water or another liquid transfers heat from the engine to the the water, if the water is not circulated then the water will become very hot and will lose all cooling heat transfer. A centrifugal water pump has a impeller powered by an electric motor or belt from the crank shaft, this impeller draws in water and forces it out circulating water through the water jacket. Because the water always flows one way through an engine, metal edges inside the engine can be rounded and obstructions can occur.

How does a raw water pump work?

A raw water pump works in the same way as a centrifugal water pump, the only difference is that the raw water pump is used to 'suck' water through the sea cock from the ocean or lake for purposes of cooling the engine.

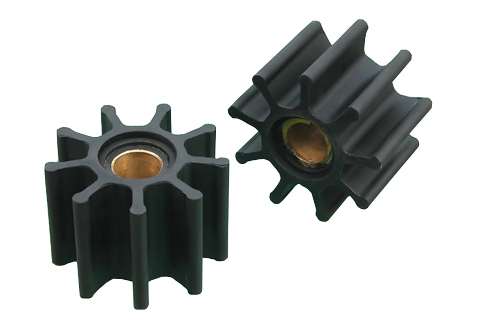

Why is it important to lubricate the impeller when fitting a new one?

The impeller serves the same purpose as the raw water pump. When a new impeller has been installed it is important to lubricate the impeller and its housing because for the first few turns of the impeller there will be no water flow to lubricate it. As a rubber impeller touches its housing this could rip the impeller apart.

A heat exchanger system.

A thermostat is a device in engines that is designed to keep temperature at a preset constant. Engines have a optimum operating temperature which the thermostat trys to control. It works like a switch and opens to release a flow of cold water through the cooling system when a preset temperature on the thermostat is reached the thermostat will open. A thermostat that does not operate correctly can make an engine overheat.

a typical thermostat

Thermostat diagram

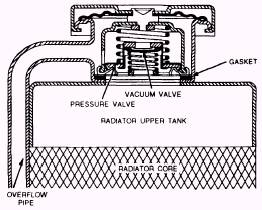

What is the purpose of a pressure cap?

The pressure cap on a radiator is for maintaining pressure in the cooling system. When water is under pressure it's boiling point increases so this makes the cooling system more effective. The pressure cap also has a bypass valve to an overflow reservoir which is activated when the engine is very hot and boiling (expanding) water needs somewhere to go to relieve pressure.

Pressure Cap diagram

Why are engines fitted with core plugs? What is the purpose of core plugs?

The core plug is a small plug on the outside of the water jacket on the cylinder block. The main purpose of the core plug is to plug up the small holes in the water jacket which are created when the cylinder block is cast. They serve other purposes too, one of which is to prevent leakage from the water jacket and also to provide a pressure outlet if the water inside the jacket freezes, ice expands and without the core plugs as an outlet the cylinder block could be cracked.

What is the core of a heat exchanger made of?

The core of a heat exchanger has to deal with high temperatures and the corosiveness of fresh and salt water. So therefore it is made of a strong metal with a high corrosion resistance. Heat exchangers come in different types like Plate type and shell and tube type heat exchanger. A plate type is now the most common and efficient type, it utilises plates with flowing hot water being cooled by cold raw water flowing through an adjacent plate.

Diagram of heat flow in a plate heat exchanger

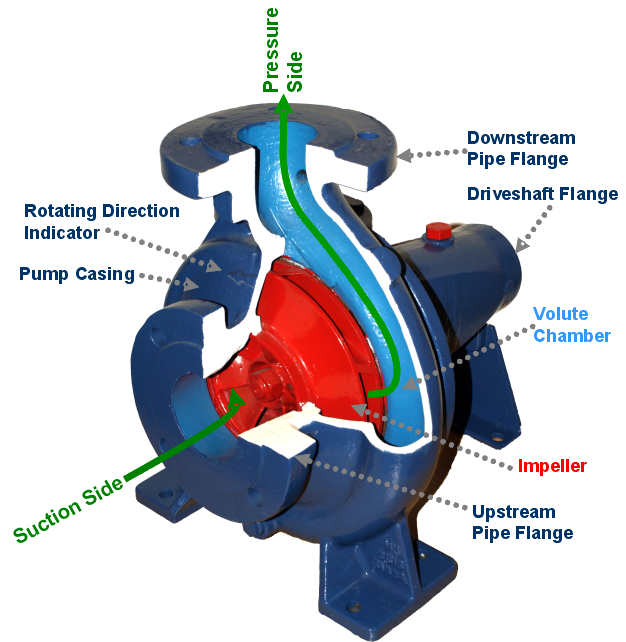

How does the centrifugal circulating water pump work?

In a liquid cooled engine, water or another liquid transfers heat from the engine to the the water, if the water is not circulated then the water will become very hot and will lose all cooling heat transfer. A centrifugal water pump has a impeller powered by an electric motor or belt from the crank shaft, this impeller draws in water and forces it out circulating water through the water jacket. Because the water always flows one way through an engine, metal edges inside the engine can be rounded and obstructions can occur.

Centrifugal pump cutaway

How does a raw water pump work?

A raw water pump works in the same way as a centrifugal water pump, the only difference is that the raw water pump is used to 'suck' water through the sea cock from the ocean or lake for purposes of cooling the engine.

Raw water pump housing and drive gear

Why is it important to lubricate the impeller when fitting a new one?

The impeller serves the same purpose as the raw water pump. When a new impeller has been installed it is important to lubricate the impeller and its housing because for the first few turns of the impeller there will be no water flow to lubricate it. As a rubber impeller touches its housing this could rip the impeller apart.

Rubber Impeller removed from housing

When refitting an impeller, checks should be made to ensure that the impeller is housed the right way but more importantly that the lock key is secured. This small lock key ensures that impeller spins with the shaft in the center by locking the impeller to it. If this is not secured the impeller will spin freely on the shaft and not draw in raw water which could overheat and damage an engine, it could also damage the impeller.

What is the purpose of an oil cooler and how does it work?

Oil just as much as coolant water can heat up to the point where it is inefficient at its job (lubrication), oil percolates at high temperatures and loses its qualities. An oil cooler transfers heat from the oil in a similar fashion to a heat exchanger. Water diverted from the raw water intake is sent to cool the oil via heat transfer. Oil has a higher boiling point than water so requires less cooling.

Automotive oil cooler

Automotive Inter cooler

Why do we have Inhibitors & antifreeze?

Antifreeze performs a variety of tasks in an engine including sealing and raising the boiling temperature of the water it is mixed with as well as lowering its freezing point. Overheating can damage parts of the engine and if the temperature is cold enough for the water to freeze the expanding ice could crack and destroy a cylinder block. Different strength mixtures of antifreeze are available. Strong mixture ratios are required in very cold or very hot areas where boiling or freezing is more common. Inhibitors are a liquid that prevents corrosion on the inside of an engine. A thin film layer of inhibitor coats the inside of the water jacket and pipes, this layer helps protect the metal from cavitation, oxidation, water flow and general wear.

An antifreeze tester measures the strength ratio of antifreeze to water

How do you test Antifreeze?

Antifreeze strength is tested with an antifreeze tester, this measures the strength of the antifreeze and tells you a percentage, from this percentage you can see whether you need to add antifreeze.

What is the purpose of a water muffle?

The purpose of a water muffler on a marine engine is to reduce the noise of the engine. Water is drawn into the engine by the raw water pump for cooling, when this water is expelled from the engine it leaves with the exhaust fumes from the engine. The water helps muffle the sound of the exhaust which is then expelled underwater at the propeller.

And just because i can again, The Strand Craft 22, a beautiful invention, with custom built super car that fits in the garage!

References:

http://www.boatsafe.com/nauticalknowhow/cooling.htm

http://www.dsmtalk.com/forums/showthread.php?t=204767

http://en.wikipedia.org/wiki/Shell_and_tube_heat_exchanger

http://en.wikipedia.org/wiki/Heat_exchanger

http://en.wikipedia.org/wiki/Plate_heat_exchanger

http://www.boatsafe.com/nauticalknowhow/cooling.htm

http://www.dsmtalk.com/forums/showthread.php?t=204767

http://en.wikipedia.org/wiki/Shell_and_tube_heat_exchanger

http://en.wikipedia.org/wiki/Heat_exchanger

http://en.wikipedia.org/wiki/Plate_heat_exchanger

Excellent work, with good research and references.

ReplyDeleteCooling in marine engineering is vital, an engine or part that creates friction and ... marineantifreeze.blogspot.com

ReplyDeleteNice post dear. I like it radiator auto & replacement radiators & radiator car

ReplyDeleteThanks for sharing this information. Find out the best manufacture and distribution of aftermarket cooling products for automotive engine cooling system. Getting touch with us on reachcooling.com

ReplyDeleteNice Post! We are leading manufacturer and supplier of air cooling system.For our manufacturing services follow us: http://www.greencon.co.in/

ReplyDeleteDirections must be perused cautiously for each piece of clothing since some garments are implied exclusively for cleaning while some for washing. Click here Master Tuna

ReplyDelete